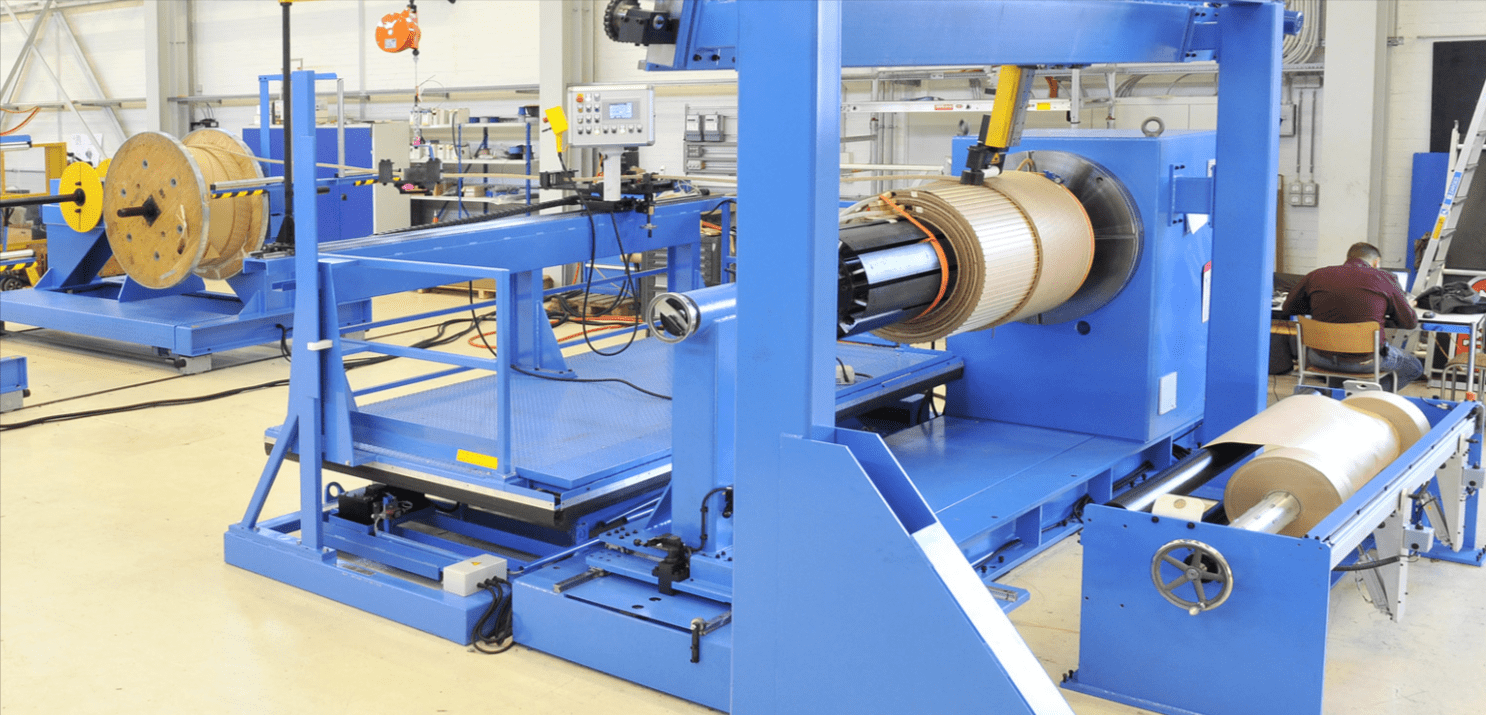

When it comes to manufacturing precision-engineered products, the China Winding Machine has become a global leader in efficiency, innovation, and affordability. As industries demand faster production rates, greater accuracy, and advanced customization, manufacturers in China have risen to the occasion with state-of-the-art winding machines designed to meet diverse industrial requirements. In this article, we’ll explore why a China winding machine is an excellent choice for your manufacturing needs, covering advanced winding techniques, industry-specific applications, and the evolution of this groundbreaking technology.

The Evolution of Winding Technology in China

Over the past few decades, China has emerged as a global hub for high-tech manufacturing. The winding machine industry has witnessed significant advancements, thanks to innovative engineering and a strong emphasis on automation. Initially focused on manual or semi-automated models, Chinese manufacturers have invested heavily in research and development to produce fully automated winding machines with unparalleled precision.

These modern machines now integrate features such as:

- Computerized controls for enhanced accuracy.

- AI-driven optimization to reduce material waste.

- High-speed winding mechanisms for increased production rates.

The result? A product lineup that can handle complex winding processes, minimize errors, and deliver exceptional output quality.

Advanced Winding Techniques

A key reason to choose a China Winding Machine is the incorporation of advanced winding techniques. These machines cater to various needs, whether for small, intricate components or large-scale industrial parts. Here are a few notable techniques:

- Layer Winding: Ideal for applications requiring precision, such as transformers and electrical coils.

- Random Winding: Perfect for mass production of components like small motors.

- Toroidal Winding: Used in producing toroidal transformers, which require specialized handling for circular cores.

- Cross Winding: Delivers a more uniform distribution of wires, essential for high-performance inductors.

The ability to customize these techniques within a single machine makes Chinese winding machines versatile and efficient.

Industry-Specific Applications

The applications of a China Winding Machine span a wide range of industries. From electronics to renewable energy, these machines are pivotal in ensuring high-quality production standards.

1. Electrical and Electronics Industry

Chinese winding machines are widely used in manufacturing components like transformers, inductors, and coils. The precision and speed of these machines ensure that products meet strict industry standards, making them essential for electronics manufacturers globally.

2. Automotive Sector

With the rise of electric vehicles (EVs), the demand for high-performance motors and batteries has skyrocketed. Winding machines from China are now integral to the production of stators and rotors for EV motors, ensuring optimal efficiency and durability.

3. Renewable Energy

In wind turbines and solar energy systems, winding machines are crucial for producing high-quality generators and inverters. Chinese manufacturers have specifically designed machines that can handle the rigorous demands of renewable energy applications.

4. Textile Industry

Beyond electronics, Chinese winding machines are also utilized in the textile sector for tasks such as yarn and thread winding. These machines ensure consistent tension and smooth operation, crucial for high-quality fabric production.

The Cost-Effectiveness of China Winding Machines

One of the biggest advantages of choosing a China Winding Machine is cost-effectiveness. Without compromising on quality, Chinese manufacturers offer machines that are competitively priced compared to their global counterparts. The reasons for this include:

- Streamlined manufacturing processes.

- Availability of raw materials at lower costs.

- High production volumes, which reduce per-unit costs.

This affordability makes these machines accessible to businesses of all sizes, from startups to large-scale enterprises.

Technological Advancements Driving the Industry

Chinese manufacturers are at the forefront of integrating new technologies into winding machines. Here are a few innovations that set them apart:

1. Automation and Robotics

Many modern machines come equipped with robotic arms and fully automated processes. These features not only improve precision but also significantly reduce labor costs.

2. Smart Control Systems

Advanced winding machines now feature IoT-enabled controls, allowing manufacturers to monitor and optimize operations remotely. This leads to greater efficiency and reduced downtime.

3. Customizable Designs

Whether you need a machine for high-speed production or intricate winding, Chinese manufacturers offer customizable solutions tailored to your specific needs.

4. Eco-Friendly Practices

With a focus on sustainability, many Chinese manufacturers are designing energy-efficient machines that use fewer resources and produce minimal waste.

Quality Assurance and Global Standards

A common misconception about Chinese products is that they may lack quality. However, this stereotype is far from the truth when it comes to winding machines. Most manufacturers adhere to international standards such as ISO 9001 and CE certifications, ensuring their products meet stringent quality requirements. Additionally, Chinese factories often implement rigorous testing protocols to ensure every machine operates flawlessly before it is shipped to customers.

After-Sales Support and Training

Another reason to choose a China Winding Machine is the exceptional after-sales support provided by manufacturers. Many companies offer comprehensive training, installation services, and ongoing technical assistance. This ensures that customers can fully utilize their machines and achieve optimal performance.

The Future of China Winding Machines

Looking ahead, the future of winding machines from China appears bright. With continued advancements in AI, automation, and sustainability, Chinese manufacturers are likely to remain leaders in the industry. Their commitment to innovation ensures that businesses around the world can rely on these machines for years to come.

Final Thoughts

The China Winding Machine is a testament to the country’s engineering prowess and commitment to excellence. From advanced winding techniques to industry-specific applications, these machines offer unmatched versatility, precision, and cost-effectiveness. Whether you’re in the electronics, automotive, or renewable energy sector, investing in a winding machine from China is a smart choice that can transform your manufacturing process.

By combining affordability with cutting-edge technology and robust after-sales support, Chinese winding machines continue to set the benchmark for excellence in industrial manufacturing. Don’t miss out on the opportunity to enhance your operations consider a China winding machine for your next project!